First-Ever Onsite Use of C-Crete’s Binder: Hubbard’s Corner Building

First-Ever Onsite Use of C-Crete’s Binder: Hubbard’s Corner Building

May 2023 , Seattle, WA

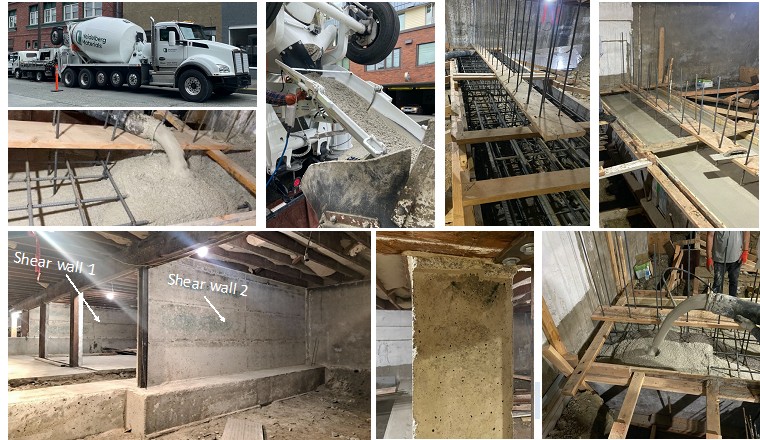

May 2023, C-Crete successfully launched its cement-free concrete product in a commercial application, delivering approximately 60 ton of its proprietary binder into the foundations and shear walls of a 120-year-old historic brick building located at 7200 Woodlawn in Seattle. This pour marked the first-ever onsite use of C-Crete’s ultra-low-carbon concrete and set a new precedent for sustainable construction practices in the United States.

The two-story, 5,126-square-foot building – originally constructed in 1912 and known as Hubbard’s Corner – was revitalized through an ambitious adaptive reuse effort led by Upward Architecture, in close collaboration with building owners Joan Crooks and Don Davies. What began as a renovation evolved into a living laboratory for cutting-edge, low-carbon construction materials and techniques. Heidelberg Materials, a global leader in construction materials, delivered the ready-mix concrete, helping enable this first-of-its-kind pour in the U.S.

This project used C-Crete’s binder as a cement replacement to modernize and strengthen the existing structure without the high carbon footprint of Portland cement, which is responsible for roughly 7% of global CO₂ emissions.

Since each ton of C-Crete binder used in place of Portland cement avoids nearly one ton of CO₂ emissions, this project resulted in a significant CO₂ savings, which is key in significant environmental benefit in reducing carbon emissions typically associated with traditional concrete. The product can be formulated from natural minerals or industrial by-products to ensure not only an ultra-low carbon footprint but also an abundant, scalable feedstock.

C-Crete’s cemet-free concrete reached compressive strengths above 5,000 psi, which is well above the typical ASTM requirement of 4,000 psi for most residential, commercial, and infrastructure applications.

The C-Crete’s concrete was easily pumped, demonstrated excellent flowability, and showed high compatibility with conventional admixtures while allowing seamless integration into existing concrete supply chains. The material also passed key durability tests, including resistance to freeze-thaw cycles, alkali-silica reaction, chloride ingress, and acid attack.

C-Crete extends its deepest gratitude to everyone who contributed to the successful launch and first onsite pour of C-Crete’s binder in a commercial application. This milestone would not have been possible without the dedication, collaboration, and belief of many outstanding partners and individuals. Special thanks to:

- The building owners, Don Davies and Joan Crooks – for championing low-carbon construction and trusting C-Crete for this groundbreaking project.

- Heidelberg Materials – for their delivery and support in ready-mix integration.

- Stuart Macalister and Larry Busch – for their ingenuity and commitment to excellence.

Learn more HERE